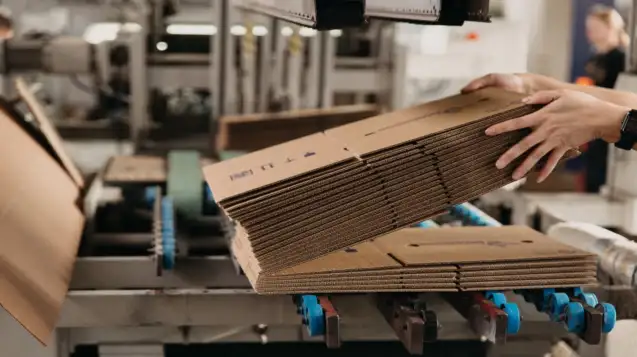

At Joyfine, quality is not an afterthought—it’s at the heart of everything we do. Through ISO-certified production processes and rigorous internal quality checks, we ensure every packaging product meets the highest standards. From material selection to final delivery, your orders are completed with precision, consistency, and care—on time and within budget.

Quality

We implement strict inspection at every stage of production. Quality assurance isn’t optional—it’s a must to earn long-term trust from our clients.

People

Our team is our greatest strength. We encourage open feedback and collaborative problem-solving to constantly refine our processes and improve outcomes.

Cost Efficiency

We reduce waste, optimize resources, and streamline workflows to lower production costs—passing those savings directly to our clients.

Always Striving for Excellence

Excellence is part of Joyfine’s DNA. Our team takes pride in delivering value through thoughtful design, precise manufacturing, and attentive service. Every department shares a single goal: help customers succeed through superior packaging solutions. Whether it’s a simple order or a complex project, our commitment to quality never wavers—and it shows in every box, cup, and carton we produce.

To meet the high expectations of global clients, Joyfine operates a dedicated quality control team and uses advanced inspection equipment to monitor every batch before it leaves the facility. From raw material verification to final product testing, we uphold strict standards at every stage. We also maintain strong partnerships with certified suppliers to ensure consistent input quality. By keeping quality at the core of our operations, we build trust that lasts—and products that perform.